| Availability: | |

|---|---|

| Quantity: | |

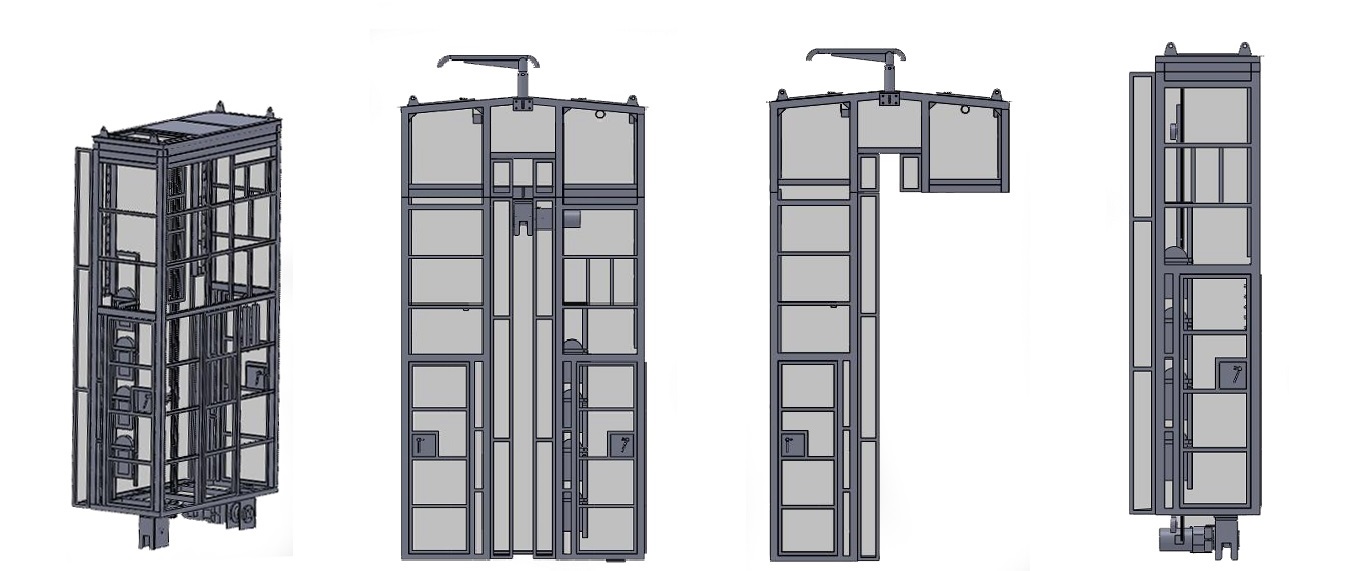

MEGW-I

WINCOO

EGW vertical gas-electric welder is an efficient automatic welding equipment according to the current feedback closed-loop to control the welding carriage improve. In a single weld pass forced by water-cooled once molding thickness from 10mm to 50mm is the main characteristic of it. Molten pool liquid level.

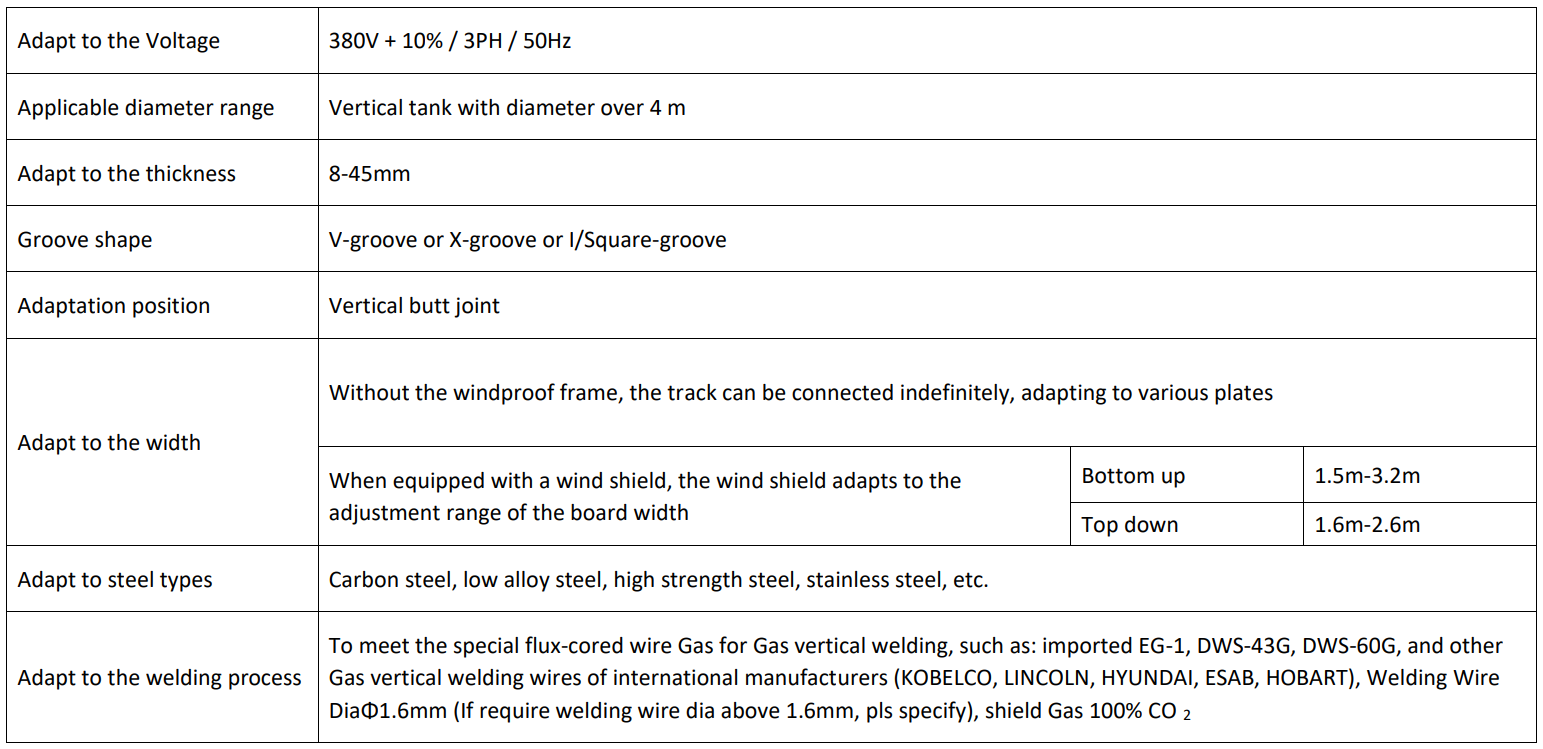

Welding Process | Electrogas welding |

Model | MEGW-I |

Plate Thickness | 8 – 45mm |

Plate Material | Carbon steel |

Groove | Single V groove;Double V groove |

Seam Position | Vertical Weld |

Min Tank Diameter | Φ6.0m |

Plate Width | 1.6 – 3.0m |

Power Input | 415V/3PH/50HZ |

Erection Method | Bottom To Top |

Dimension(L x W x H) | 4000mm x 1900mm x 1100mm |

Gross Weight | 1200kg |

Construction Site Pictures of Tank Vertical Welding Machine

Construction Site Pictures of Tank Vertical Welding Machine

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.Based client's facility/site space availability, we are able to study/design and present matched configurations on project schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

What we can bring to you?

1, Support you to win the project during bidding phase. We can provide your more suitable configurations to help you shorten the constrcution time.

2, We can provide all technical documents and advices to support you for construction procedure clearifications

3, We can support you to calculate the roughly construction time based one welding efficiency, the calculation of manpower needed, welding consumbles quantity

4, We can provide your suitable welding consumbles with much more competetive price from our long time business partner if you need.

5, We can provide site people training service, and operation service or manpower service or as a subcontractor.

Sign up for our newsletter to receive the latest news.

Copyright © 2020 WINCOO ENGINEERING CO.,LTD

Support By:Leadong